Automated Tablet Dispensing & Packaging System

It integrates with HIS system to automatically receive and process medication order information, then to dispenses unit dose oral tablets or capsules, packaging into the same pouch with printed patient and medication information. It affords such functions as tablet expiration date management and alarm, inventory management, manual dispensing progress monitoring, shortage alarm reminder, and past prescription and medication querying.

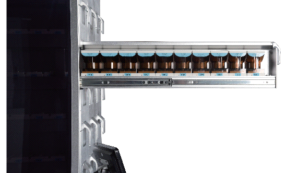

Drawer-Type Storage Strcture

Drawer-Type design is convenient for equipment cleaning. Each drawer can store 20 intelligent canisters, and there are total 18 drawers (expandable) which can store 360 canisters. The independence among drawer modules can shield the exception of the module so as not to affect the normal operation of other modules. The drawer and the pedestal of each canister come with indicator lights which will be on when there is shortage of tablets in relevant canisters, making it easy for pharmacists to find and fill tablets.

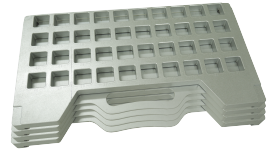

Intelligent Medication Canister (Universal canister is optional)

It has five specifications and the maximum storage capacity is 5000 tablets;

Each medication canister has an embedded chip to support self-recognition of its location and tablet information no matter where it is installed.

Tailored mold chip has the characteristic of precision and accuracy, ensuring the correct number of tablets dropped each time. Both large and small tablets can be filled into the canister.

The mold chip is independently self-developed and self-produced, which can quickly respond to customer’s needs. It only takes 7 days from the customer's request to the completion of the new canister.

Adopting a light-resistant design, it has a wide range of applications and can store light-resistant tablets.

Built in sensor is used for precise counting.

Manual Dispensing Unit (MDU)

It has 40 cells and can be expanded up to 120 cells. It can realize the advance manual dispensing and batch filling of non machine-stored tablets. One MDU has four independent transmission chutes, each of which is independently controlled.

Packaging & Printing Module

The modular design ensures system stability. The packaging and printing module can be pulled out as a whole, facilitating the replacement of packaging pouches and ink ribbons. Shenzhen RSS has independently developed technology that can print fonts on transparent or opaque side. The printed fonts are clear and not easily faded, very suitable for pharmacist’s verification use.

Dual Temperature Control System

The equipment adopts a dual sealing-knife mode, with dual heating tubes and dual temperature controllers. When it is heated to 85 degrees Celsius the pouch sealing will be completed, reducing damage of tablets caused by temperature, and ensuring the dispensing speed and efficiency.

Intelligent Tablet Dispensing System

12 inch movable touch-screen display;

Can seamlessly integrate with HIS system, quickly and accurately processing medical order information.

Equipped with a voice control system, the system can complete dispensing work through voice commands, and can also provide error messages such as tablet shortage and accident through voice reminder.

Provides remote real-time monitoring and protection.